OMRON has introduced the OL-450S, a low-profile omni-directional autonomous mobile robot designed to streamline material handling tasks. The new robot is built to optimize workflows by transporting roll cages, trolleys and similar load carriers with a payload capacity of up to 450 kg. Its compact design allows it to navigate complex facility layouts in industries such as automotive, semiconductor and electronics, food and household goods and medical. By delivering reliable and consistent transport, the OL-450S aims to enhance operational efficiency while maintaining high safety standards for personnel.

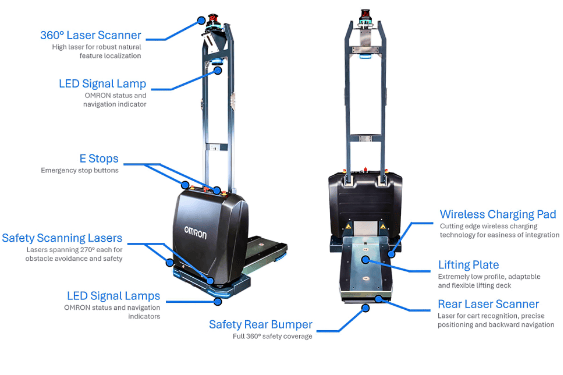

A key feature of the OL-450S is its integrated lifting plate which supports lifting heights ranging from 108 mm to 308 mm and lifting weight capacity of 450 kg. This built-in mechanism removes the need for custom attachments or rack toppers, enabling plug-and-play compatibility with both standard and custom racks. With this flexibility, businesses can adopt the robot without modifying existing infrastructure and thereby reduces installation time and capital expenditure. The design ensures that material movement processes integrate smoothly into current operations.

In addition to its lifting capability, the OL-450S offers advanced navigation and centralized fleet management. Equipped with omni-directional drive and 360-degree safety coverage, the robot avoids obstacles and adapts to changing layouts using its strategically positioned sensors. Wireless charging further simplifies deployment by eliminating manual charging tasks. OMRON’s FLOW Core software provides a unified platform to manage fleets of up to 100 robots with varying payloads. By combining these features, the OL-450S delivers a comprehensive solution for automating material transport in fast-paced industrial environments without requiring any infrastructure modifications.